Are you trying to choose from the different types of 3D printing for your next project? This straightforward guide cuts through the complexity, offering a clear view of the prominent 3D printing technologies – FDM, SLA, DLP, SLS, and beyond. You’ll learn not just about each method’s intricacies but how they apply to real-world applications. Dive in to make an informed choice on the technology that best fits your creative or industrial ambitions.

Key Takeaways

3D printing encompasses various additive manufacturing technologies such as FDM, SLA, SLS, DMLS, DLP, MJF, and EBM, each with unique processes suited for different applications.

Technological strengths vary, with FDM being cost-effective for prototyping, SLA and DLP providing high precision, SLS and DMLS for complex geometries in functional parts, and MJF for high-speed, multi-material production.

The choice of 3D printing technology depends on the project’s requirements, including factors like resolution, speed, material properties, and cost constraints, ensuring the selection is tailored to the specific application.

Understanding 3D Printing Technologies

The foundation of 3D printing lies in additive manufacturing, which involves using computer control to deposit layers of material and create objects. Despite its apparent simplicity, this field has a wide range of diversity. Various types of additive manufacturing technology exist, each having its own unique methods for constructing objects such as selective laser sintering, fused deposition modeling (FDM), stereolithography (SLA), digital light processing (DLP) and more.

These technologies have significantly progressed since they were first introduced in the 1980s and now offer faster production rates for small to medium-sized items compared to traditional manufacturing techniques.

Additive Manufacturing Technology encompasses various processes like Selective Laser Sintering(SLS), Fused Deposition Modeling(FDM), Stereolithography(SLA), etc., where materials are layered on top under precise computer guidance resulting in an object’s formation. With advancements made over time across all these technology spectrums, one can cite that significant strides towards accelerated creation patterns, especially concerning smaller-to-medium sized projects, which far exceed those done via conventional means.

Despite the seemingly simplistic concept behind it, additive manufacturing has gone from just being another fad back when it was launched around the early 80s to represent cutting-edge technology today. Now blending into many industries due to recognition brought about by improved operations parameters sourced mainly by ‘selective-laser-sintering,’ along with other progression modes originating from Additive Manufacturing itself.

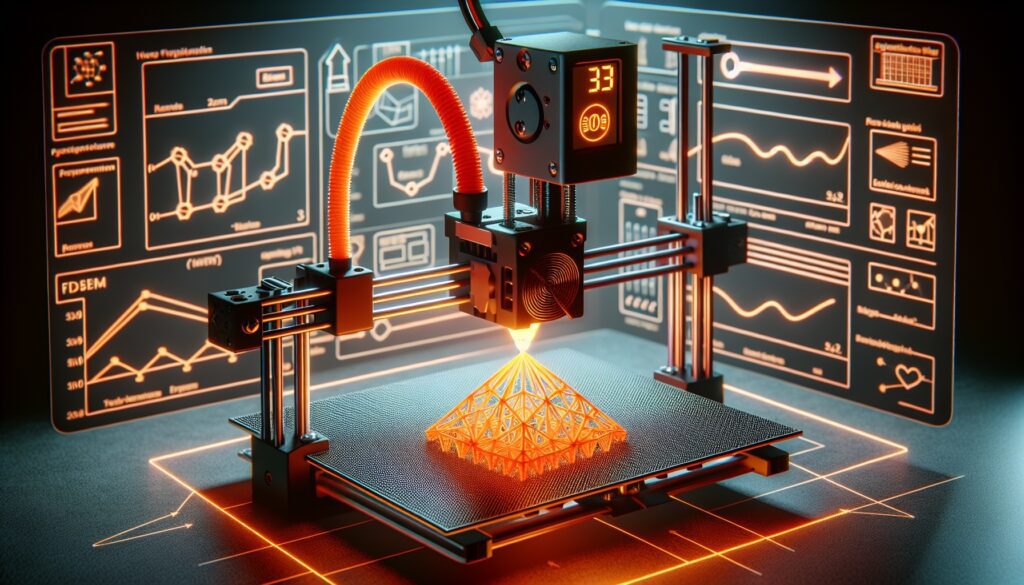

Decoding Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) has gained popularity due to its cost-effectiveness. This technology is commonly seen in desktop 3D printers and involves the deposition of layers of melted material following a path outlined by a CAD model. To visualize, it’s like controlling a hot glue gun with precision using robotic control. The accuracy and quality of the final product are maintained through this method as each layer adds to its overall completion.

The most widely used materials for FDM include ABS and PLA. There are other options available, such as Polypropylene, that can also be successfully utilized.

Materials and Applications

FDM technology provides a wide range of material options, including ABS, PLA, PETG and their blends, as well as specialized materials. Each type has its own unique characteristics to offer, such as the high tensile strength of PLA or the toughness of ABS. PETG is specifically preferred for applications requiring strength but not as much shrinking as you would find in ABS. These materials have diverse uses in various industries, from producing intricate functional prototypes and durable manufacturing tools to creating low-volume production components and rapidly validating conceptual models through prototyping.

Advantages and Limitations

Similar to any other technology, FDM has its own set of positives and negatives. Its notable advantages include a diverse range of materials, affordability, and ease of use. It also comes with some drawbacks like limited material options, challenges in producing intricate details, and a rougher final surface compared to alternative technologies.

The Precision of Stereolithography (SLA)

Stereolithography (SLA) is a great option for those in need of precise results. It is an additive manufacturing method that utilizes UV light to cure photopolymer cross-sections with extreme accuracy, transforming them from liquid to solid form. This unique ability allows SLA to excel in producing high-precision components by hardening the liquid resin with pinpoint precision.

From Liquid Resin to Solid Objects

SLA printers utilize a range of resin materials to produce precise and intricate components. The key factor is the interaction between UV light and the resin, which causes it to solidify and gradually build up each layer of the object with remarkable detail.

This technique resembles sculpting with light, where every thin layer plays a crucial role in shaping the final structure of the object. Just like adding layers upon layers in traditional sculpture methods, each step adds depth and definition until an accurate representation is achieved through utilizing precisely controlled UV exposure on these delicate yet powerful resins.

Crafting with Light: Applications of SLA

SLA’s remarkable accuracy and level of intricacy has made it a popular choice in various sectors, including aerospace, automotive, and medical fields. Its capability to produce casting patterns, prototypes with complex designs, as well as applications for the healthcare industry highlights the diversity of this technology.

Sintering Layers with Selective Laser Sintering (SLS)

Moving on, we will discuss the fascinating technology of Selective Laser Sintering (SLS), a form of 3D printing. In this process, layers of powdered particles are selectively fused using a laser beam. It can be compared to building a sandcastle with powder and laser instead of traditional sand and water.

One key advantage is that SLS has the capability to work with various materials, such as polymers and metals, making it highly versatile in its applications within 3D printing.

Material Choices in SLS

SLS relies heavily on materials, such as Nylon PA12 and glass beads for polymers or aluminum and titanium for metals. The versatility of SLS allows it to work with a range of these materials, each providing distinct mechanical properties and visual appeal.

Industrial Uses of SLS

SLS is highly sought after by industries like aerospace, automotive, and medical due to its versatility. It’s capable of producing intricate shapes and strong functional components. This technology has revolutionized these fields with its capacity for printing large quantities of parts precisely while offering flexibility in design options.

Direct Metal Laser Sintering (DMLS) & Its Industrial Impact

Direct Metal Laser Sintering (DMLS) is an ideal method for those seeking to produce robust metal components. It utilizes a laser beam to bond particles of metal powder together, resulting in highly detailed and strong parts.

The materials typically employed in DMLS are selected based on their specific requirements for mechanical properties such as strength, durability, and other characteristics necessary for support structures. These may include aluminum, maraging steel, stainless steel, and titanium.

These particular metals are utilized due to their suitability in material extrusion processes used during DMLS. They provide the needed level of strength and resilience required for support structures while maintaining intricate detail when fused through direct metal laser sintering techniques into final metallic pieces.

Metal Alloys and Properties

DMLS technology is capable of utilizing various metal alloys, each contributing distinctive characteristics to the end product. Among the commonly used alloys in DMLS are:

Stainless steel: known for its exceptional resistance against corrosion

Aluminum: offering high strength and increased flexibility in design

Titanium: recognized for its unparalleled strength-to-weight ratio

The availability of these diverse alloys expands the potential applications and allows for greater versatility in designs when using DMLS.

Revolutionary Applications in Manufacturing

The use of DMLS is causing a major shift in industries such as aerospace, automotive and medical. This advanced technology has the capability to manufacture intricate metal parts that were previously unattainable using traditional manufacturing techniques.

From crafting complex engine components for aircrafts to producing personalized implants for medical purposes, DMLS is bringing about significant changes. Its ability to create lightweight yet highly detailed metal pieces has had a tremendous impact on various fields.

Digital Light Processing (DLP): Speed Meets Precision

The digital light process, also called DLP, is a technology that effectively combines speed and accuracy. Using a digital light projector to solidify photopolymers, this method can produce objects with incredible precision in significantly less time than other 3D printing techniques.

The Role of the Digital Light Projector

At the heart of DLP technology is the digital light projector, which plays a crucial role in its functioning. By projecting an image onto each layer of resin, it triggers solidification according to the desired pattern. This unique feature allows DLP to work at remarkable speeds.

In terms of accuracy, the ability of the projector to display intricate images for every individual layer enables DLP to achieve unparalleled precision. Its exceptional capability in projecting precise and complex patterns sets it apart from other technologies in this aspect.

Where DLP Shines: Use Cases

The precision and swiftness of DLP technology make it a top choice for tasks that require intricate designs. Whether used to create delicate jewelry or precise dental devices, DLP is revolutionizing multiple fields.

Its capability to produce detailed miniature objects has also made it popular in the toy and model sector, where its quality workmanship is highly sought after.

Multi Jet Fusion (MJF) for Functional Prototypes

The industry has been greatly impacted by Multi Jet Fusion (MJF), an advanced 3D printing technology known for its ability to produce multi-material and multi-color parts with speed and precision. While other techniques like material jetting build layers, MJF uses a fusing agent, heat, and infrared light to create detailed parts from powdered thermoplastics. This unique process sets it apart from other technologies such as material jetting in terms of accuracy and detail.

Multi-Material Printing Capabilities

One of MJF’s notable strengths is its ability to handle a wide range of materials. Some examples include Nylon PA12, which can be mixed with glass beads for added strength (up to 40%), as well as Nylon PA11 and Polypropylene PP.

Each material brings its own distinct characteristics to the finished product, making it possible for clients to achieve a high level of customization. With various options available, individuals can select the ideal material that meets their specific needs and preferences.

The Edge of MJF in Production

MJF serves as both a tool for creating prototypes and a powerhouse for production. Its capabilities include quick printing, accurate capturing of intricate details, effectiveness in large-scale manufacturing processes, and cost-effectiveness per component.

These qualities have revolutionized the way industries such as healthcare, automotive, and manufacturing operate by enhancing their efficiency levels.

Binder Jetting: Versatility in Powder Form

Binder Jetting is a fascinating form of 3D printing that involves strategically applying liquid binding agents onto powdered materials. It has the ability to work with various substances, including metals, ceramics and sand, offering endless opportunities for innovation.

Binder Jetting Process and Materials

The process of binder jetting starts by using a bed of powder material, similar to that used in the powder bed fusion method. A special printhead then applies a binding agent, functioning like an adhesive, which binds the particles together and creates a solid object. This technique offers great versatility as it can be applied to various materials such as metals, ceramics, and sand. Each presents unique characteristics and visual appeal.

Applications Across Industries

The process of binder jetting has made its way into multiple industries due to its ability to work with different materials. Its functions range from producing multicolored prototypes, manufacturing intricate metal and ceramic parts, to creating molds for sand casting. The automotive sector specifically utilizes this technology extensively for quick prototyping and the production of complex components.

Electron Beam Melting (EBM): Fusing Metal Particles with Precision

One of the most notable metal 3D printing methods is Electron beam melting (EBM) due to its ability to produce sturdy and compact parts. This technique involves using a high-energy electron beam to melt and combine tiny metal particles, similar to an incredibly precise welding process.

It excels particularly well in working with metals such as titanium and cobalt, both renowned for their strength and long-lasting properties. EBM’s main advantage lies in its effectiveness at fusing together these durable materials into complex shapes through the use of focused energy from an electron beam.

The Mechanics of Electron Beam Technology

EBM’s impressive capability lies in its electron beam, which has a high level of energy that is utilized to specifically heat and merge metal powder particles. As the particles bond together, they form a solid component with distinct mechanical characteristics and lower levels of residual stress.

Due to this unique process, EBM excels at producing robust parts that require exceptional strength and endurance, such as those used in aerospace industries or for medical implants.

EBM in Action: Aerospace and Beyond

Electron beam melting (EBM) is highly favored in the aerospace and medical fields for its capability to produce strong components. It has been instrumental in manufacturing sophisticated aircraft turbine blades and other essential parts, as well as tailor-made medical implants. Its versatility in handling high-temperature materials and alloys prone to cracking makes it a valuable asset within these rigorous industries.

Navigating the Landscape of 3D Printing

Choosing the right 3D printing technology can be a difficult task due to the abundance of options available. It is important to assess your project’s specific requirements before making a decision. Are you in need of high-quality parts? In this case, SLA or DLP may be suitable choices. For metal printing, it would be beneficial to consider technologies such as DMLS or EBM. If speed is your priority, FDM or MJF could meet your needs best. Ultimately, various factors should play into your decision-making process including printer type and cost along with resolution and required materials.

Summary

We have explored the intriguing realm of 3D printing technologies, ranging from well-known choices such as FDM and SLA to advanced industrial options like SLS, DMLS, MJF, and EBM. Each technology has its own unique advantages and limitations that make it suitable for various purposes and materials. Whether you are a hobbyist seeking intricate designs or a manufacturer looking to streamline production processes, there is definitely a specific 3D printing technology available to cater to your requirements. So let’s embrace this revolutionary power of 3D printing and shape our future one layer at a time.

Frequently Asked Questions

What are the 3 types of 3D printing?

There are three main categories of 3D printing techniques: stereolithography (SLA), selective laser sintering (SLS), and fused deposition modeling (FDM). Each approach has its own advantages and produces distinct printed components. One such method, selective laser sintering, involves using a focused laser to fuse powdered materials together in layers. Another technique is fused deposition modeling which employs an extrusion process to create objects by depositing materials.

What is the difference between FDM and SLA?

The primary distinction between FDM and SLA is the type of materials they employ and their mode of operation. Unlike FDM, which uses heated thermoplastic filament to construct objects in a layer-by-layer approach, SLA utilizes UV light to solidify liquid photopolymer for creating three-dimensional shapes.

SLA is great for smaller, more detailed parts like minis that you would find on a board game. On the other hand, when you get into larger pieces, like an electronics cover, FDM is a more cost-effective process.

Which 3D printing technology is the fastest?

Multi Jet Fusion (MJF) and Fused Deposition Modeling (FDM) are the leading 3D printing technologies due to their exceptional speed in creating objects. These methods, known for their fast print times, have become increasingly popular among users looking for quick and efficient production processes.

What materials can be used in 3D printing?

In the world of 3D printing, various materials can be utilized to create objects such as metals like titanium and aluminum, plastics including ABS and PLA, as well as ceramics and sand. These are among the most commonly used substances for this innovative technology.

Metal alloys, plastic polymers, ceramic composites, and sand particles are all viable options when it comes to producing three-dimensional prints through the process of additive manufacturing. This versatile method allows for a versatile method.